Tokyo University of Marine Science and Technology

Using RTR-500 Series for Temperature and Power Supply Management in Fish Tanks at Tokyo Bay Waterfront Site in Tateyama

Tokyo University of Marine Science and Technology needed to find a way to manage temperature and power (lighting and heating) for sea water tanks and cultivation water tanks at their research and marine education field lab site in Tateyama, Chiba. They needed to monitor not only on-site, but from far away. As they were dealing with living organisms they needed a system that would send warning notifications by e-mail when a temperature measurement exceeded a set upper or lower limit. They also needed to be alerted when abnormalities in the power supply to heating and lighting devices occurred.

Products

The RTR-500 Series has been discontinued and replaced by the improved RTR500B Series. The following links will provide information about the successor model.

RTR-500 Series

-

Temperature

-

Voltage

-

Wireless Base Station / Repeater

-

Network Base Station

-

RTR500B

Series

T&D Solution

System Setup

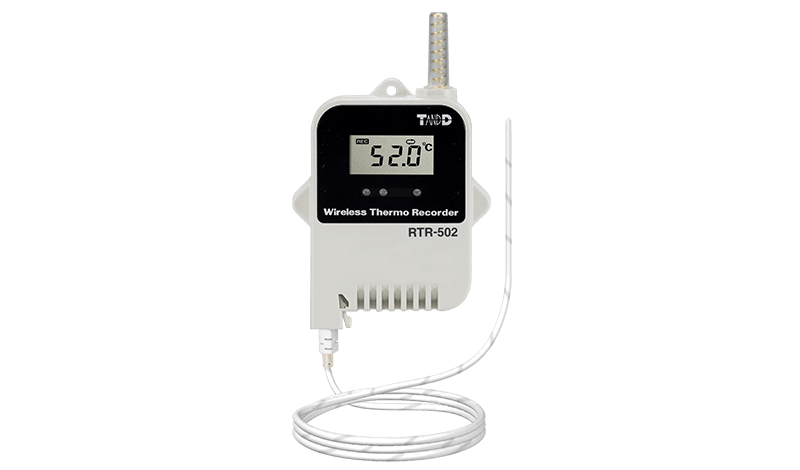

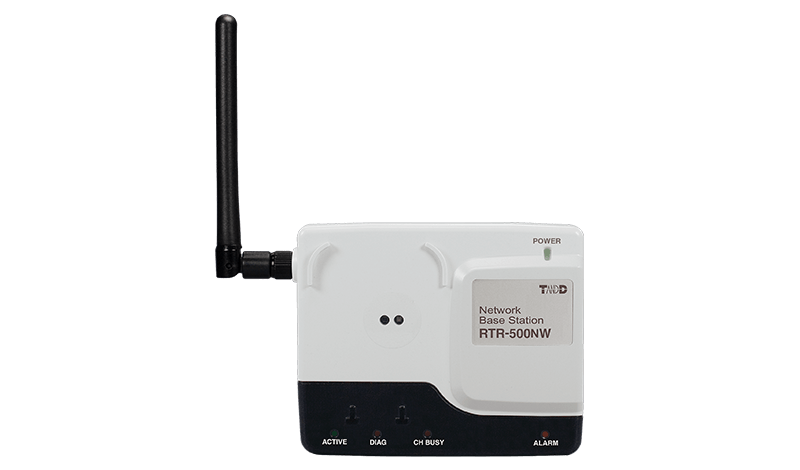

A system was set up using the Remote Units (RTR-502) with their compact, durable and IP64 water resistant bodies to measure and record sea water and tank internal water temperature. Repeaters were introduced as necessary to extend wireless radio communication between Remote Units and the Base Station. The Base Station (RTR-500AW) was chosen for its wireless LAN compatibility which allowed them to take advantage of an already existent onsite LAN network. Furthermore, to monitor for power supply abnormalities RTR-505-V voltage loggers connected to a nylon hinge one time clamp type sensor were used.

Usage

Although the RTR-502 loggers themselves are IP64 rated, for additional protection they wrapped the sensor connection area in a plastic bag. The Remote Units were placed in areas where wireless radio communication with the Base Unit was stable. In places where communication was unstable they introduced a Repeater (RTR-500) to extend the communication range. Settings were made so that all of the data from various points was automactically collected into the Base Unit and tranferred via wireless router to the control PC where data could be monitored, analyzed and stored. Warning notification limits and settings were also made for the sending of warning e-mails upon rises or drops in temperature. As the RTR-505-V comes with a module connecter it was easy to connect the bare wires leading from the clamp sensor directly into the module connected to the RTR-505-V. The clamp sensor itself needed no power supply and output voltage in the range from DC0-5V.

Results & Merits

By using the wireless LAN compatible RTR-500AW it was possible to take advantage of the internet networking already on site to monitor and log temperature with the compact water resistant RTR-502 as well as voltage with the RTR-505-V connected to the suitable sensor. The use of a wireless network also made it possible to receive large bulks of data from a number of measuring points at a PC distant from the site. Moreover, the warning notification system allowed for e-mails to be immediately sent to the set addresses when a measurement fell below or rose above the set limits or when there was an abnormality in the power supply to the lighting or heating equipment.